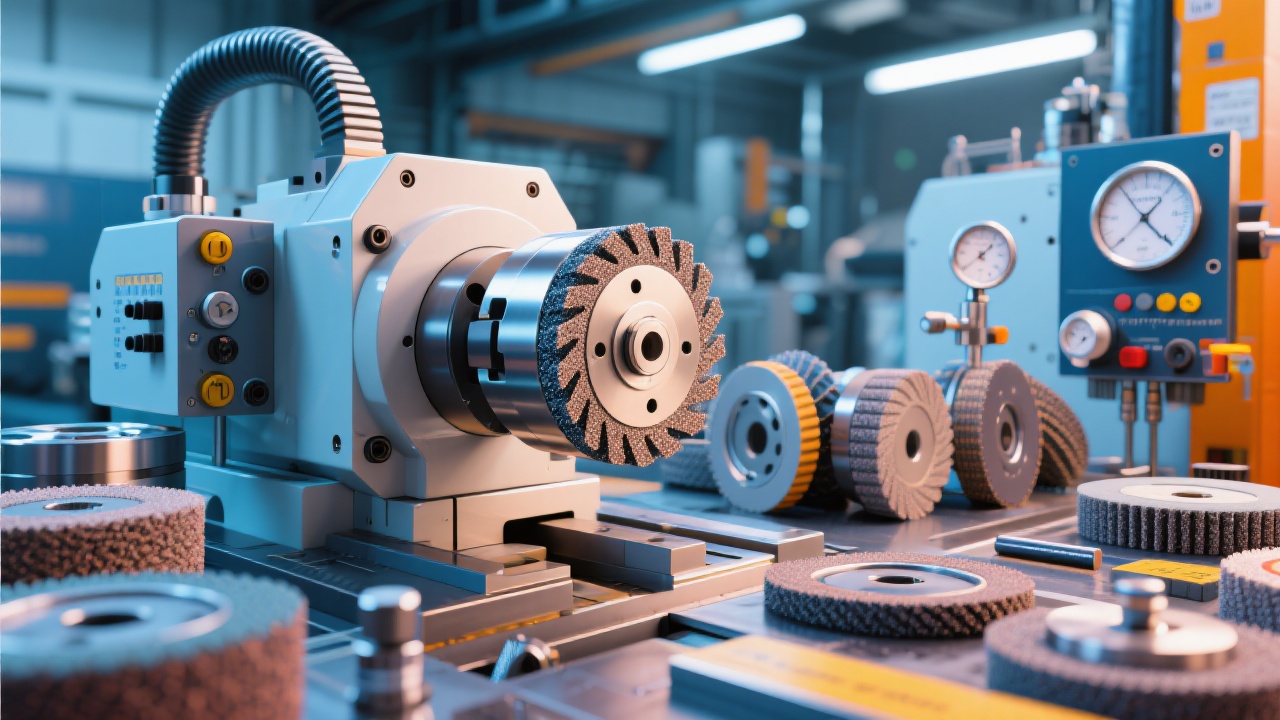

Henan Youde Superhard Tools Co., Ltd has set a new benchmark in abrasive technology through its Sintered Diamond Grinding Wheels 400 series. Engineered specifically for the rigorous demands of grinding nodular cast iron, grey iron, ceramics, and rubber composites, these wheels bring a remarkable blend of longevity, efficiency, and environmental stewardship to industrial grinding operations.

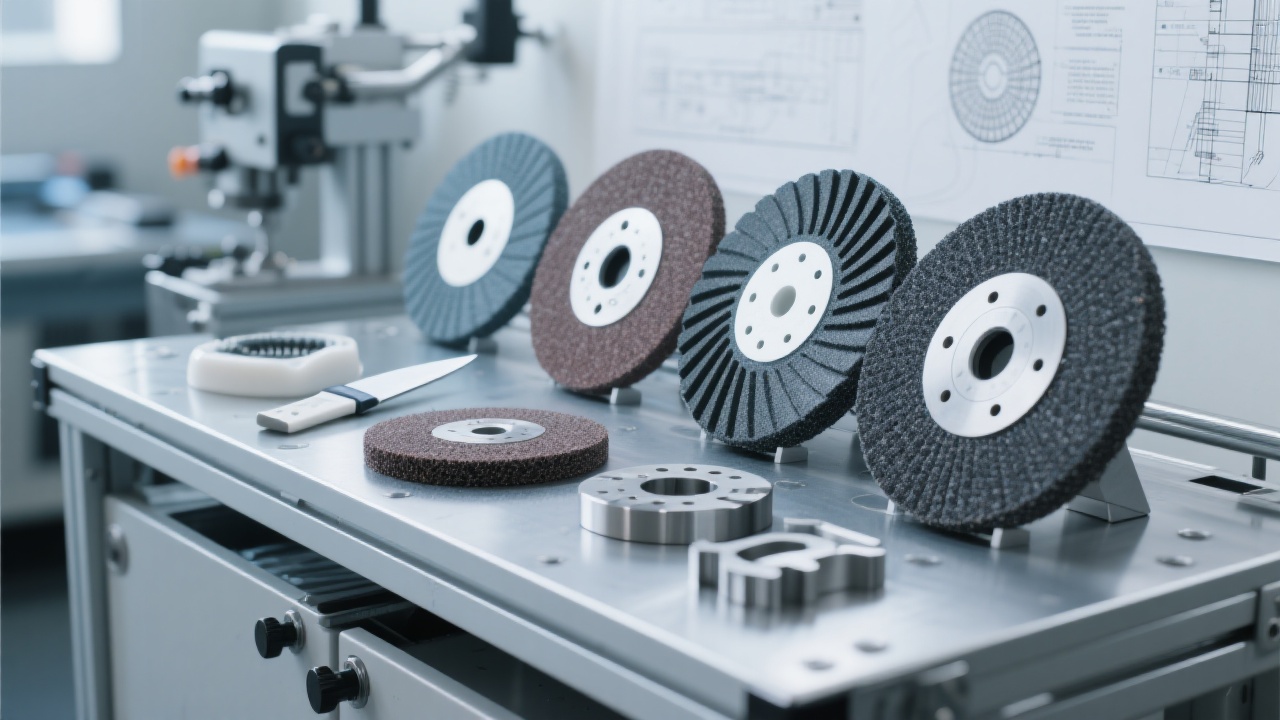

At the core of the 400 series lies a careful selection of ultra-high-quality synthetic diamond particles. These diamonds possess enhanced hardness and optimized particle size distribution, which significantly improve the abrasive capability and lifespan of each wheel.

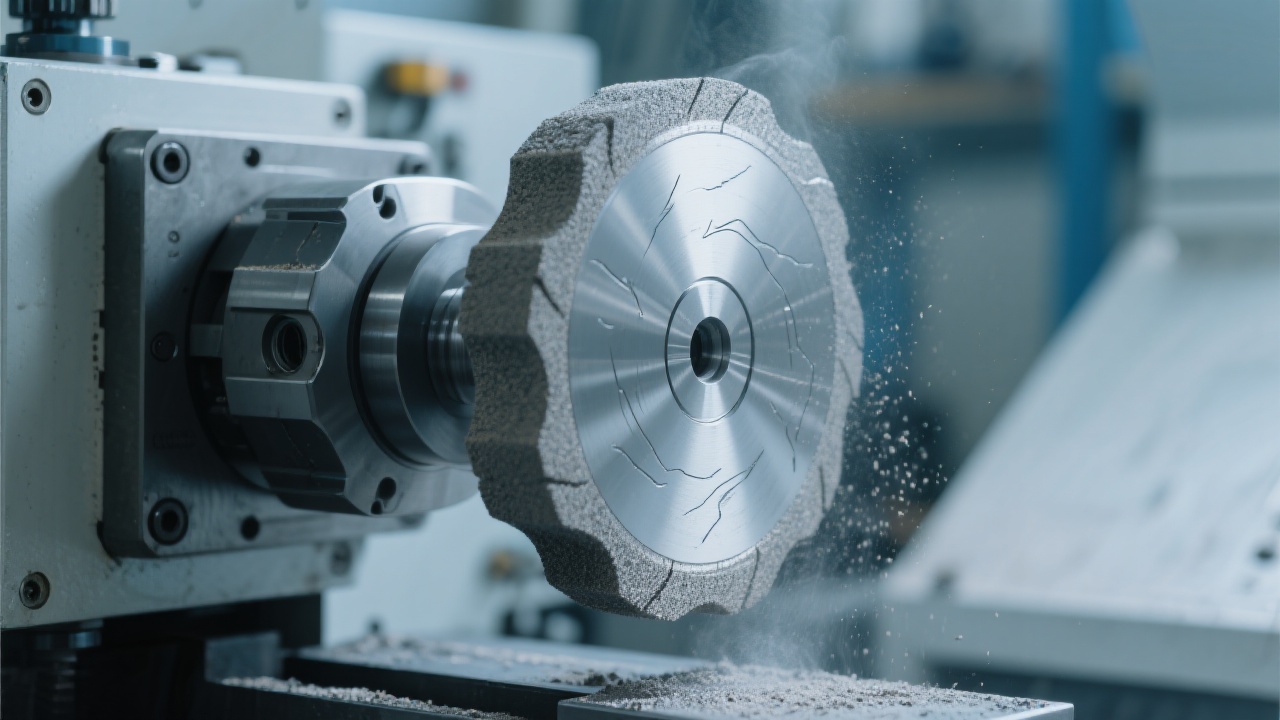

The application of cutting-edge vacuum brazing technology ensures a robust and uniform bond between the diamond grit and the metal substrate. This technique not only maximizes the retention of diamonds during high-stress grinding but also reduces thermal distortion and material loss, which is often observed in traditional bonding methods.

Such innovations contribute to a reduction in abrasive dust emissions by up to 30%, promoting a safer and healthier work environment. Moreover, vacuum brazing facilitates environmentally friendly production processes with minimal hazardous waste byproducts.

When tested under industrial conditions, the Sintered Diamond Grinding Wheel 400 demonstrated a 40% longer operational life compared to conventional resin-bonded diamond wheels. The wheels exhibit superior grinding efficiency with a 25% increase in material removal rate on cast iron surfaces, leading to shorter cycle times and higher throughput.

Furthermore, the wheels provide exceptional surface finish quality on ceramic and rubber components, reducing the need for secondary finishing processes and thus saving additional labor and material costs.

| Performance Metrics | Sintered Diamond Grinding Wheel 400 | Conventional Resin-Bonded Wheel |

|---|---|---|

| Operational Life (hours) | ~120 hrs | ~85 hrs |

| Material Removal Rate (mm³/s) | ~8.5 | ~6.8 |

| Dust Emission Reduction | 30% less | Baseline |

A leading manufacturer of automotive ceramic components integrated the Youde Sintered Diamond Grinding Wheels 400 in their precision grinding lines. Over a six-month evaluation period, the client reported a 35% improvement in grinding efficiency and a 22% reduction in wheel replacement frequency. Operational downtime was cut by 18%, translating into significant productivity gains.

Moreover, the reduction in fine abrasive dust contributed to better compliance with workplace safety regulations and enhanced operator comfort, boosting overall workforce morale.

Environmental responsibility is a core design principle behind the 400 series. The wheels' efficient material removal lowers energy consumption per production unit, while the vacuum brazing method drastically curbs the generation of hazardous dust.

Independent laboratory tests confirm that dust particulate emissions generated during grinding drop by approximately 30% compared to conventional grinding wheels, positively impacting respiratory health and regulatory compliance for industrial users.

In sectors where precision, durability, and environmental standards are increasingly vital—such as automotive, aerospace, and electric vehicle battery manufacturing—the advantages offered by the Youde 400 series create compelling value propositions. Its extended lifespan, high efficiency, and ecological benefits empower manufacturers to achieve cost savings and competitive sustainability credentials.

When considering grinding solutions, companies benefit from prioritizing tools that not only enhance output but also safeguard the health of their workforce and the planet.

The strategic decision to use Youde Sintered Diamond Grinding Wheels 400 ultimately supports businesses in not just meeting, but exceeding production and sustainability goals.