Manufacturers striving for precision and productivity in processing hard materials understand the critical role of high-performance abrasives. The UD Diamond Soldered Grinding Wheel 400 Series, expertly crafted by Henan Youde Ultra-hard Tools Co., Ltd., emerges as a reliable solution engineered to optimize grinding of ductile iron, grey cast iron, ceramics, rubber, and more. This article provides an in-depth exploration of the 400 Series’ unique product positioning, technological innovations, and practical application insights tailored to export processing factories focused on efficiency and cost control.

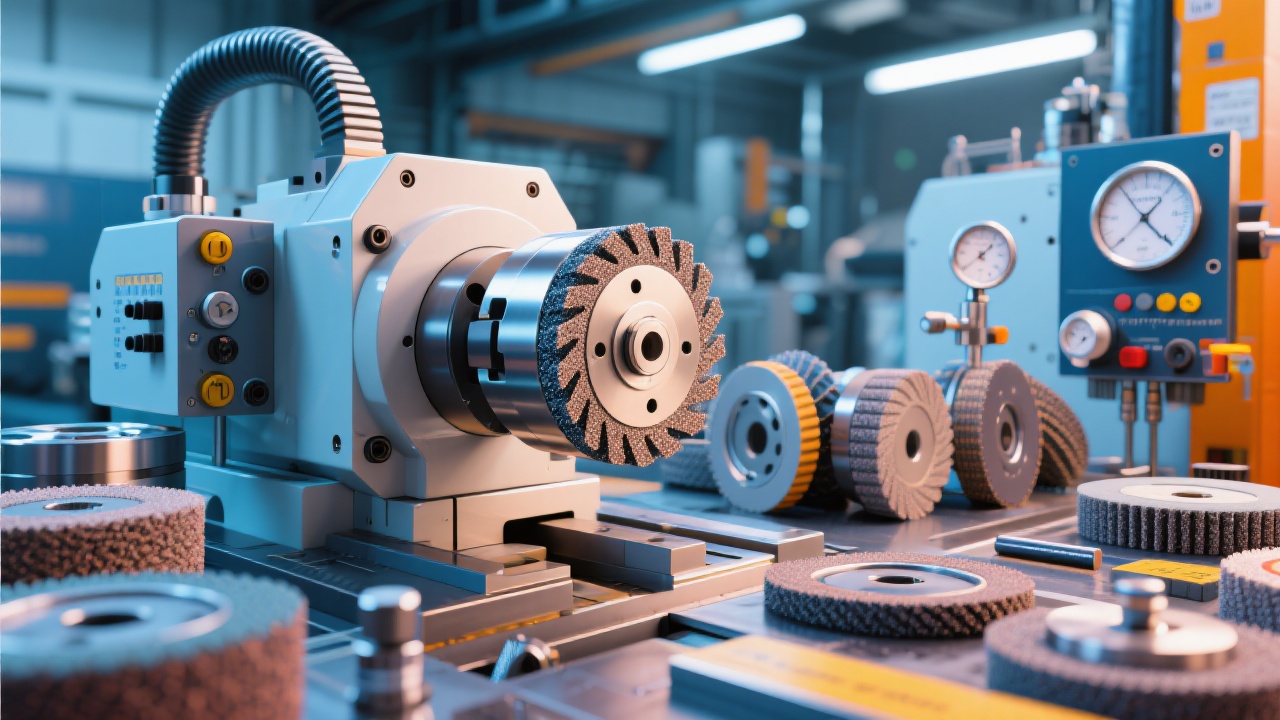

Positioned as a top-tier soldered diamond grinding wheel, the 400 Series integrates industry-leading abrasives with advanced vacuum soldering technology. Its standout features include:

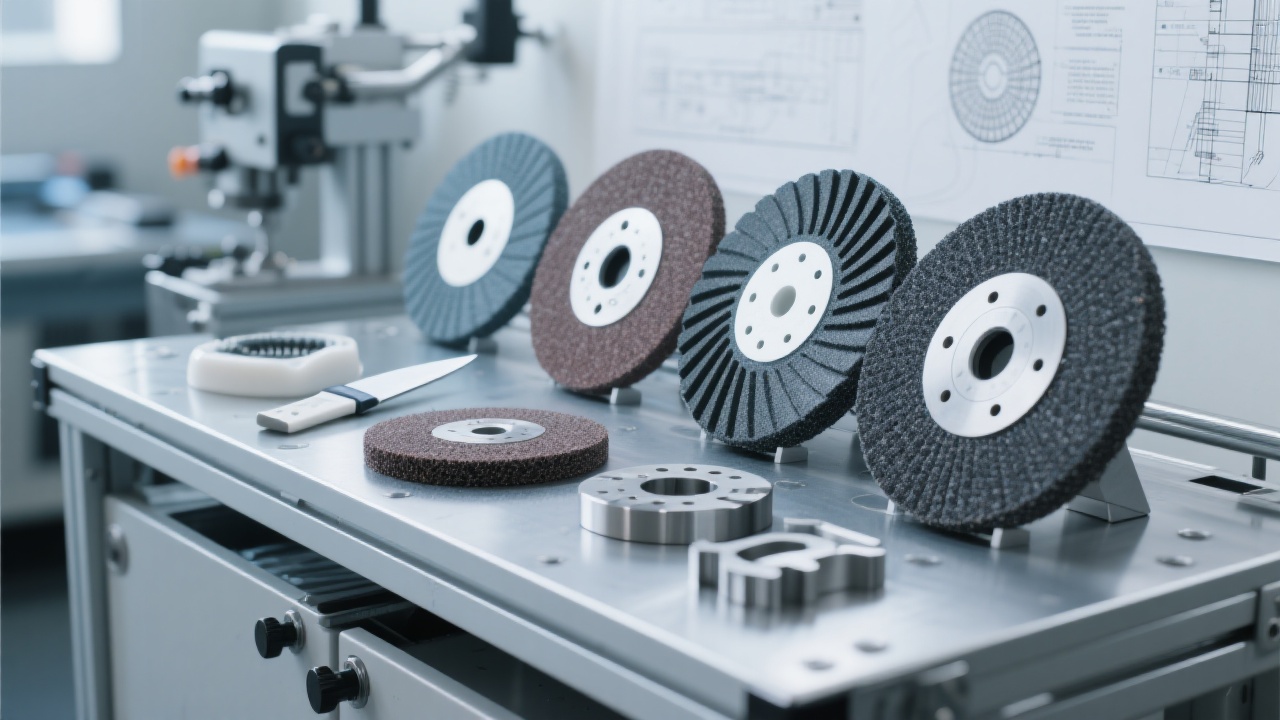

The 400 Series is available in various diameters (100mm – 400mm) and thicknesses (6mm – 20mm) to adapt to different grinding machine standards and operational demands. Precision surface grinding and profile shaping are well supported across the range.

| Material | Grinding Wheel Compatibility | Recommended Abrasive Specs |

|---|---|---|

| Ductile (Nodular) Cast Iron | 400 Series, 200-300mm diameter | Diamond grit size 150–200 mesh |

| Grey Cast Iron | 400 Series, 150-250mm diameter | Diamond grit size 120–180 mesh |

| Ceramics | 400 Series, up to 400mm diameter | Superabrasive grit size 180–240 mesh |

| Rubber Compounds | Specialized 400 Series wheels, 100-150mm diameter | Diamond grit size 200 mesh |

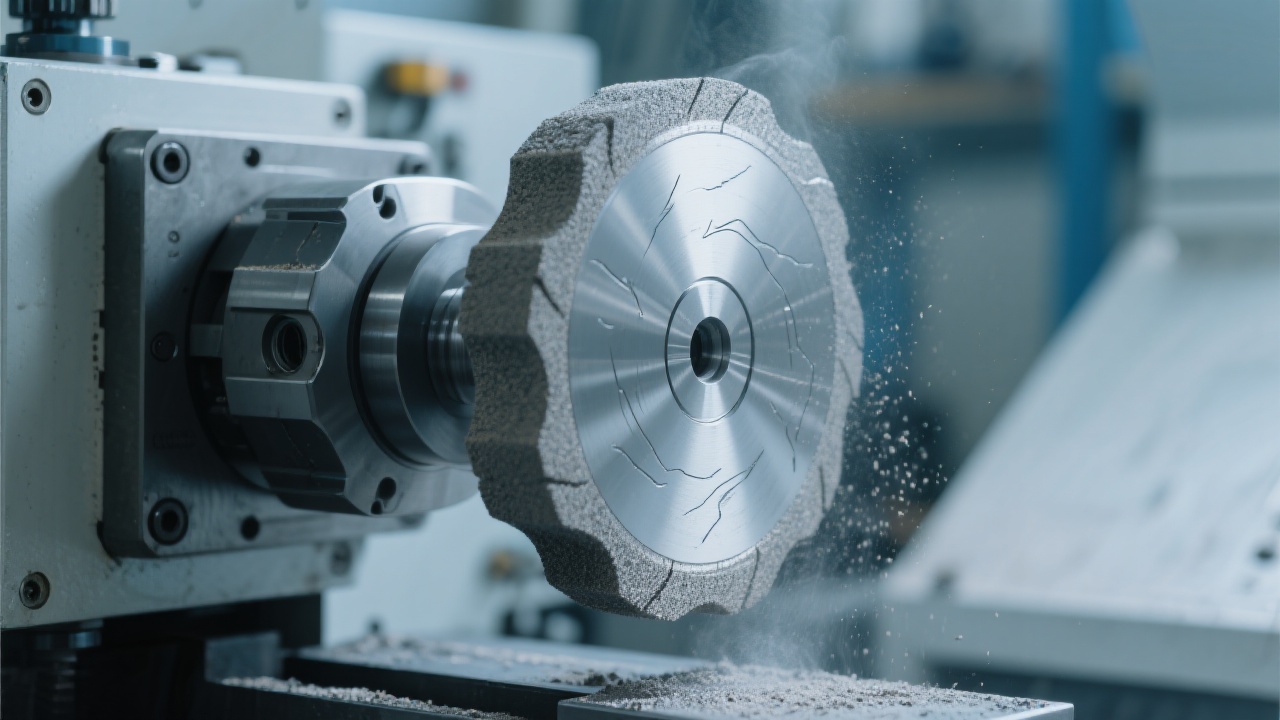

Central to the 400 Series’ exceptional performance is the innovative vacuum soldering cloth technique, ensuring diamond particles are uniformly embedded with strong metallurgical bonds. This results in:

Combined with stringent diamond selection standards (purity above 98%, controlled morphology), these manufacturing processes secure consistent quality and prolonged operational lifespan—critical factors for high-demand export processing plants.

A leading export factory specializing in automotive component finishing adopted the 400 Series to machine ductile iron brake discs. Over six months, key performance indicators improved dramatically:

These results translated to a considerable reduction in operational costs and enhanced customer satisfaction, key drivers for maintaining competitive exports.

To maximize benefits, export processing plants should consider the following when choosing their grinding wheels from the 400 Series:

By tailoring physical and operational parameters to specific processing demands, clients can reliably elevate both efficiency and output quality.

Besides manufacturing excellence, the 400 Series stands out for its eco-conscious design:

This thoughtful approach aligns with the growing international demand for green manufacturing practices, endorsing UD’s commitment to responsible industrial development.

Are you ready to elevate your export manufacturing competitiveness through smart abrasive solutions? Discover the full capabilities of the UD Diamond Soldered Grinding Wheel 400 Series today and empower your operations with enhanced efficiency, prolonged tool life, and sustainable performance.